Hotline: +86 (0)510-85580506 / 85580509

Hotline: +86 (0)510-85580506 / 85580509

Your current location: Home > Technical Support >> General Instructions

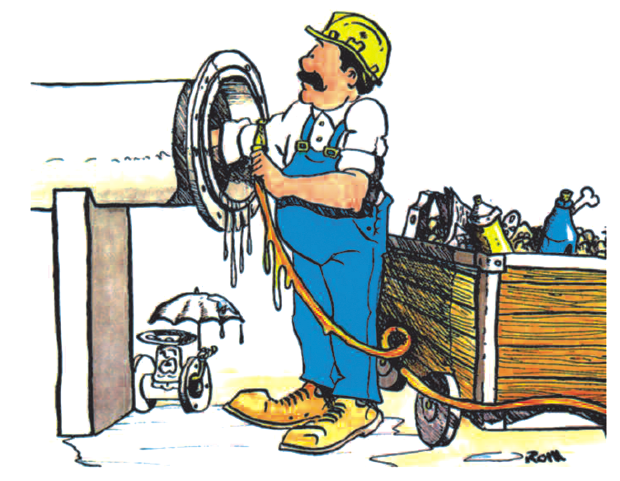

◆ Clean the pipes

Before the tests and starting of lhe installations ,carry out the abun- dant rinsing of piping(water ,air ,steam if compatible). It is essential to eliminate all the particles and various objects which could remain in the pipes and particularly welding residues which could definitively damage the valve seat.

◆ Align Pipings

Check piping alignment. Do not rely on the valves to correct bad alignments:risk of leakage,operating defect or even breaking.

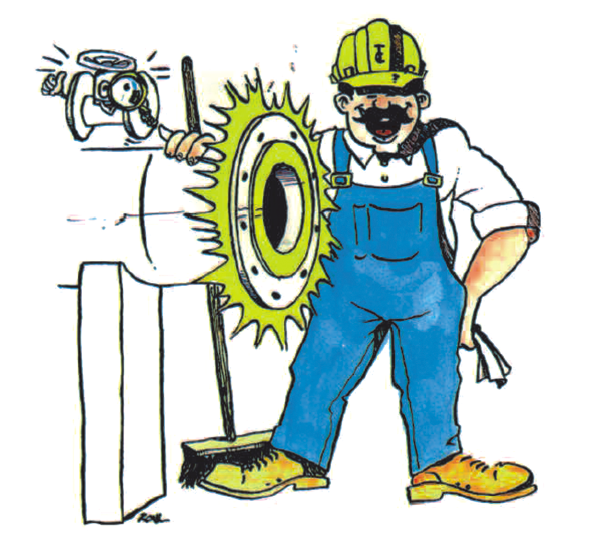

◆ Clean the gasket seat

Before assembling,take care that the gasket seats are perfectly clean free from stripes prejudicial to good tightness.

◆ To avoid the “water hammers”

A water hammer can generate a rise in pressure of extreme brutality. The damage caused by a water hammer is considerable:butterfly valve disc splits,axes deformed,destroyed various apparatuses. The causes of the water hammers are very varied but generally:the starting of pump and the sudden closing of valve.Attention,when starting the installation or testing ,take all the necessary precautions slow down motorized valves.

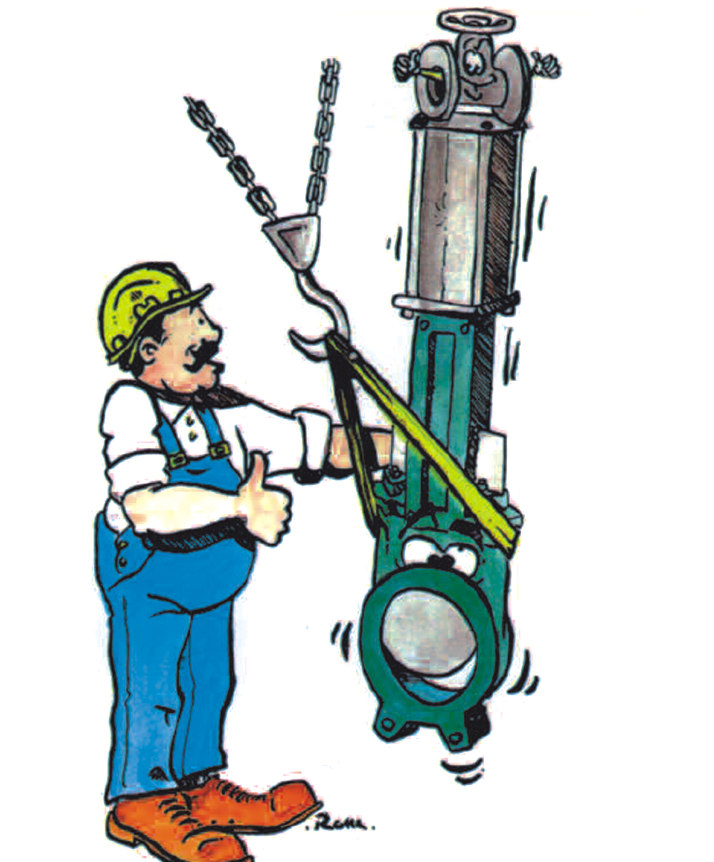

◆ Handle the valves with precaution

Sling valves by the body. Do not hang at the handwheel or the servo-moto. Attention with the shocks.

◆ Respect assembly direction

Some valves are one-way(non-return valve ,knife gate valves,etc). Take care of an assembly in conformity with the arrow direction or of the instructions of assembly.

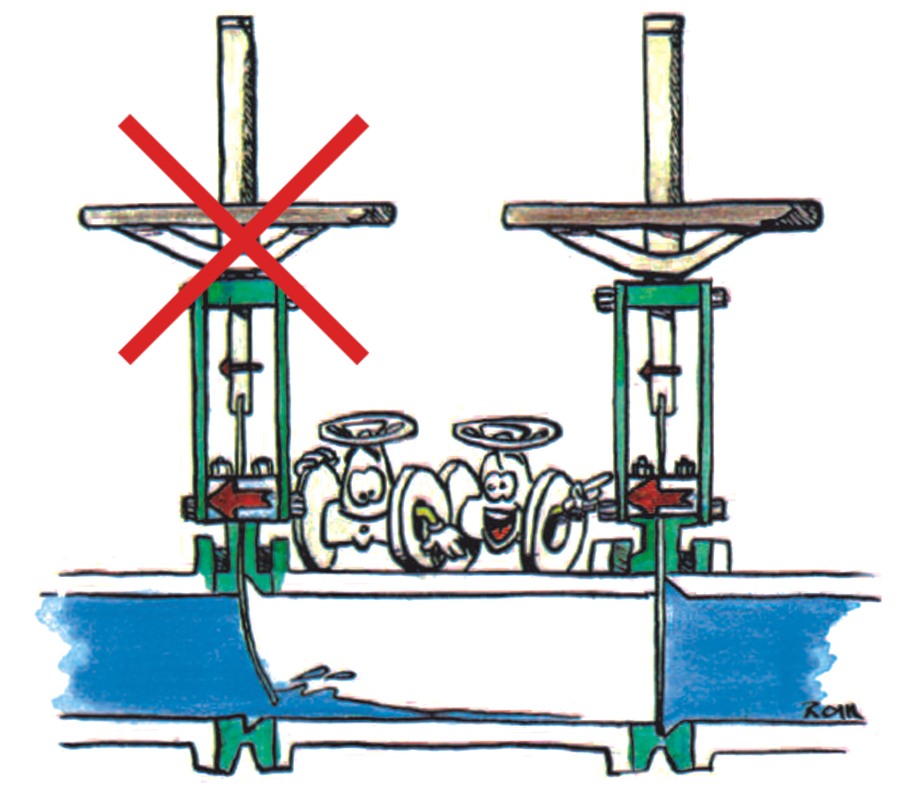

◆ Support the valves

Before the tests and starting of lhe installations ,carry out the abun- dant rinsing of piping(water ,air ,steam if compatible). It is essential to eliminate all the particles and various objects which could remain in the pipes and particularly welding residues which could definitively damage the valve seat.

◆ To respect the tightening torques

It is prejudicial applying higher tightening torque than needed. This can create markings on the seats and ,premature wears particularly for the rubber seat (diaphragm valves).

◆ Weld valves opened

Take care, when welding steel or stainless valves ,that the position is open.

◆ To handle valve with precaution

Take care of the coatings and protections. To avoid shocks and frictions which ,by destroying the coatings ,create starters of corrosion.

◆ Store the equipment under good conditions

The valves must be stored protected from:

Humidity and rain to avoid corrosion;

Wind,sand: to avoid the penetration of solid particles whose presence is catastrophic for the tightness;

Sunshine and heat: they damage the coatings,particularly harmful for plastic valves and fittings very sensitive to the ultraviolet.

Valves with rubber seat must always be stored half-opened.

The apparatuses with metal seat must be stored closed (except particular specifications) to avoid the penetration of the particles in internal volumes.

Ball valves must be stored in open position.

Preserve the apparatuses with their plastic caps which should be taken away when mounting the valves.

◆ Guarantee

Unless otherwise advised and without prejudice to the legal guarantee,VCV offer a guarantee of twelve months from the date of placing the goods at disposal in our premises,it covers only the repairing of the goods stated defective.The customer must inform VCV by letter of attributed vices on the goods and supply any justification on the subject.The guarantee does not apply to: ①the components,which by their materials nature or by their function suffer erosion ②in case of deterioration or accidents caused by:any modification or intervention on the original product;the no-respect of the installation,the use or the maintenance instructions and defect on supervision, in storage or maintenance;an installation or use not in accordance with the book . ③in case of no-payment.

◆ Instruction Generals

Use: ①To bring into service the installation after control.②For temperatures higher than 60℃ do not touch the body of the equipment under pressure and provide a protection.③To use adapted flanges.④The used compressed air must be clean,dry and lubrificated according to the standard lSO 8573-1;⑤For actuator and solenoid valve,use compressed air conforming tothe purity class of lSO 8573-1 4/3/4;⑥For the air of control(pneumatic positioner),use compressed air conforming to the purity class of lS0 8573-1 2/3/3.

Maintenance and control: ①Control the valves yearly.②Change the gaskets after each disassembling.③Any maintenance action must be carried out when the installation is in the atmospheric pressure.④Cut energy supply of the actuators.