Hotline: +86 (0)510-85580506 / 85580509

Hotline: +86 (0)510-85580506 / 85580509

Your current location: Home > Our Advantage >> Permanent Quality Control

Vincent counts on the most developed equipments to carry out all control

and testing operations: hydraulic and pneumatic air tightness testing , dimensional control ,material

control,operating and resistance testing.

|

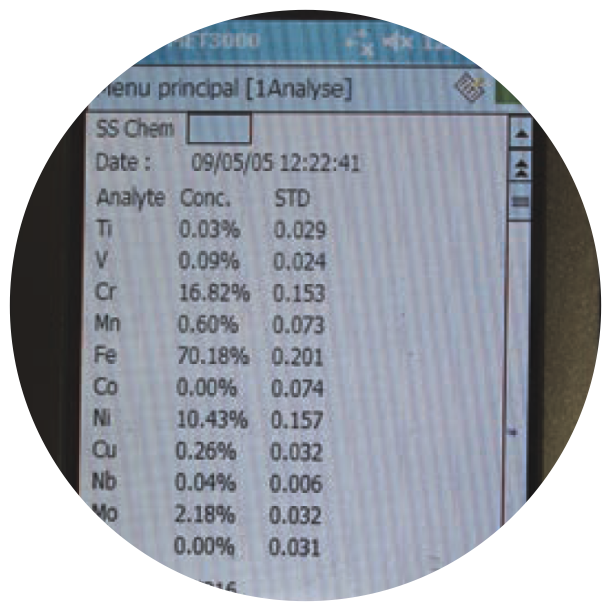

① Material Control Chemical analysis by spectrometer. |

|

||

|

|

|

|

|

|

|

|

② Metal Hardness Test Mechanical property test especially after heat treatment. |

|

|

|

|

|

|

|

|

|

|

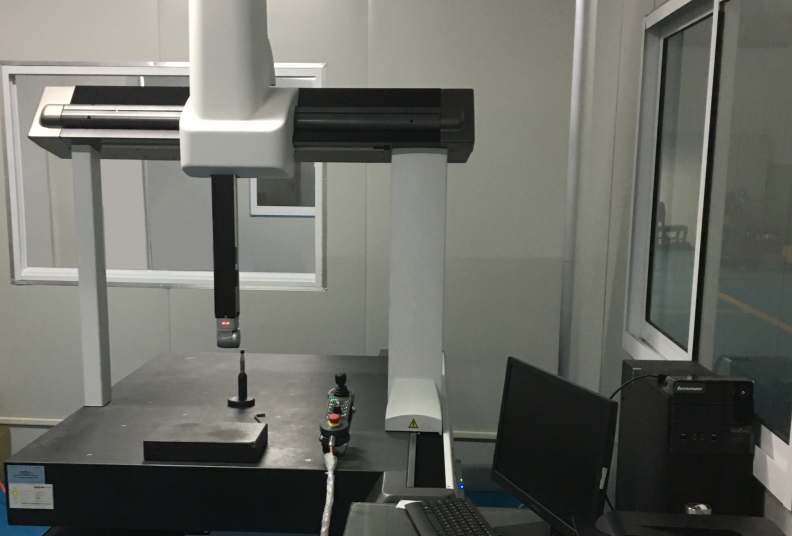

③ XYZ Test XYZ test of tolerance and size exactly according to the drawing. |

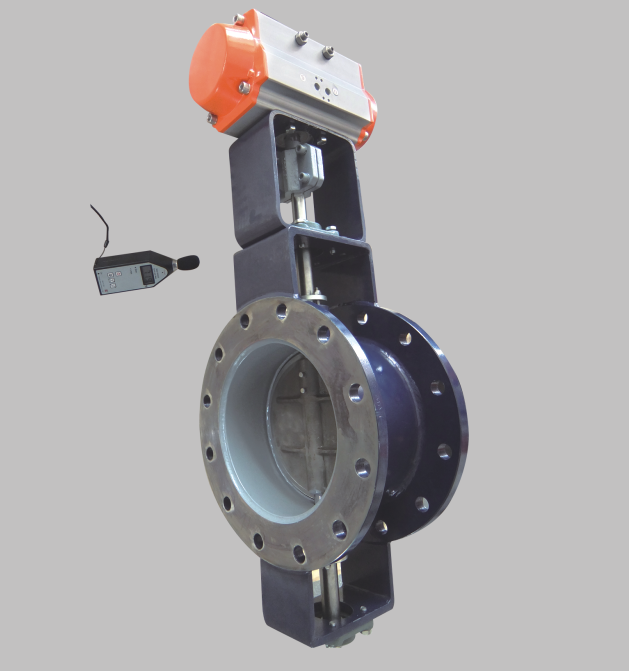

④ Noise Test

Environment protected by reducing noise of the valve. |

|

|

|

|

|

|

|

|

|

⑤ Metal Thickness Test Thickness test to ensure the shell resistence. |

|

|

|

|

|

|

|

|

|

|

⑥ Coating Thickness Test Anti-errosion property made assrurance by thickness test after Epoxy painting and coating. |

|

|

|

|

|

|

|

|

|

|

⑦ Torque Test Torque control to adapt to suitable actuator enlength using life. |

|

|

|

|

|

|

|

|

|

|

⑧ Hydraulic Tests Bi-direction test for every single piece of valve to make sure the sealing performance . |

|

|

|

|

|

|

|

|

|

|

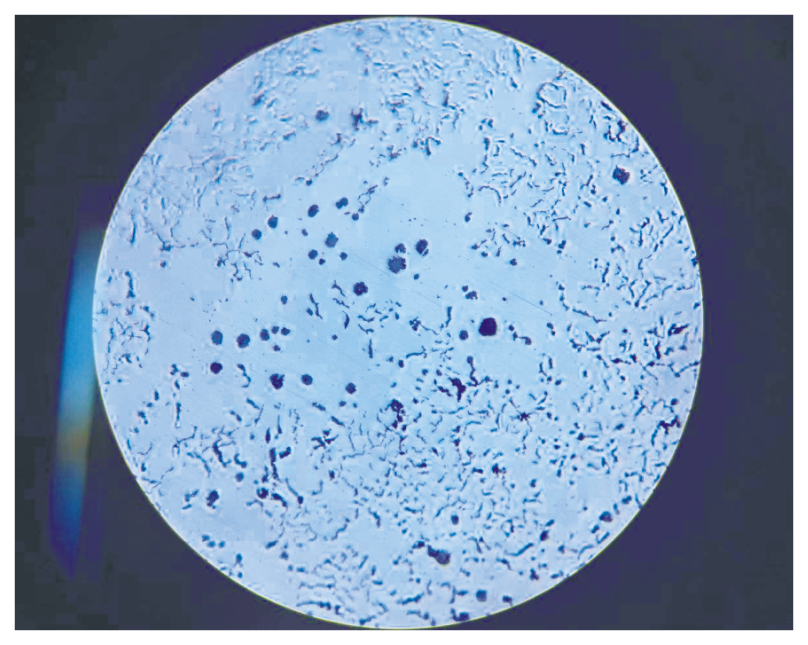

⑨ Rate of spheroidization Test the rate of spheroidization every batch, less than level four. |

|

|

|

|

|

|

|

|

|

|

Hardness test for sealing part to zero leakage. |

|

|