文森特使用控制检测设备进行测试,液压和气压密封测试,尺寸检测,原材料检测,工作性能及寿命测试。

Vincent counts on the most developed equipments to carry out all control and testing operations: hydraulic and pneumatic air tightness testing , dimensional control ,material control,operating and resistance testing.

|

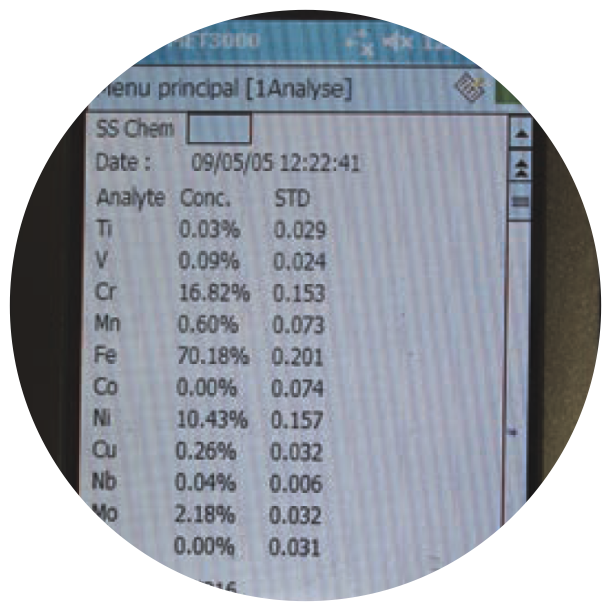

① 材质成分控制 Material Control 光谱仪检测,对材质进行化学元素分析。 Chemical analysis by spectrometer. |

|

||

|

|

|

|

|

|

|

|

② 金属硬度测试 Metal Hardness Test 力学性能分析,特别是热处理后的零件。 Mechanical property test especially after heat treatment. |

|

|

|

|

|

|

|

|

|

|

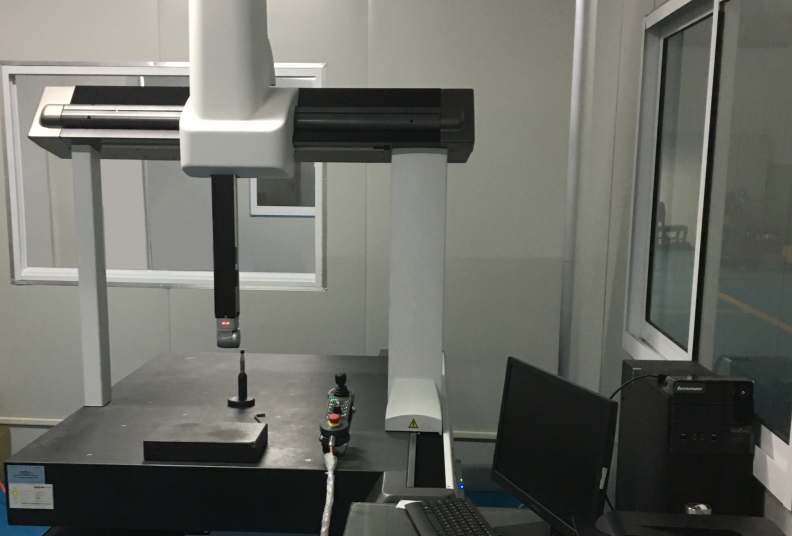

③ 三坐标检测 XYZ Test 运用精密仪器对零部件进行检测,保证零件尺寸、形状和形位公差满足图纸要求。 XYZ test of tolerance and size exactly according to the drawing. |

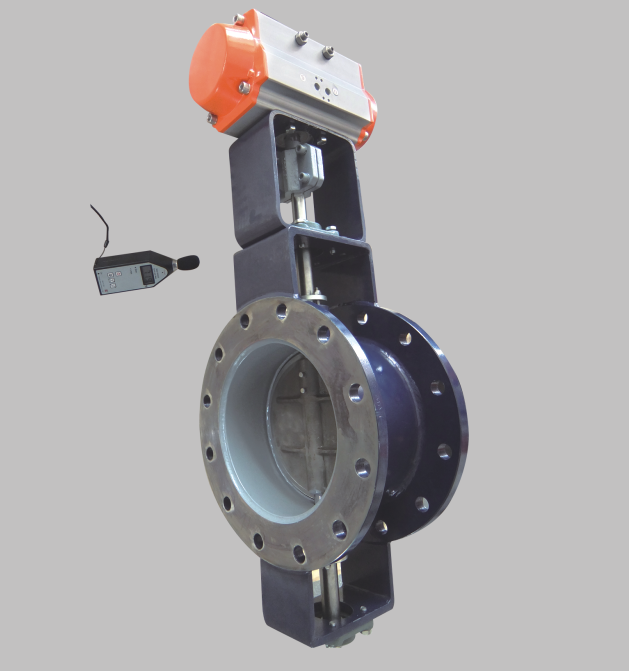

④ 噪音测试 Noise Test 控制噪音,环境保护。 Environment protected by reducing noise of the valve. |

|

|

|

|

|

|

|

|

|

⑤ 金属壁厚测试 Metal Thickness Test 壁厚测试,确保壳体承压满足设计要求。 Thickness test to ensure the shell resistence. |

|

|

|

|

|

|

|

|

|

|

⑥ 涂层厚度测试 Coating Thickness Test 控制涂层厚度,保证防腐蚀性能。 Anti-errosion property made assrurance by thickness test after Epoxy painting and coating. |

|

|

|

|

|

|

|

|

|

|

⑦ 扭矩测试 Torque Test 扭矩控制以适配执行器,延长使用寿命。 Torque control to adapt to suitable actuator enlength using life. |

|

|

|

|

|

|

|

|

|

|

⑧ 压力测试 Hydraulic Tests 100%双向压力测试,保证阀门的密封性能。 Bi-direction test for every single piece of valve to make sure the sealing performance . |

|

|

|

|

|

|

|

|

|

|

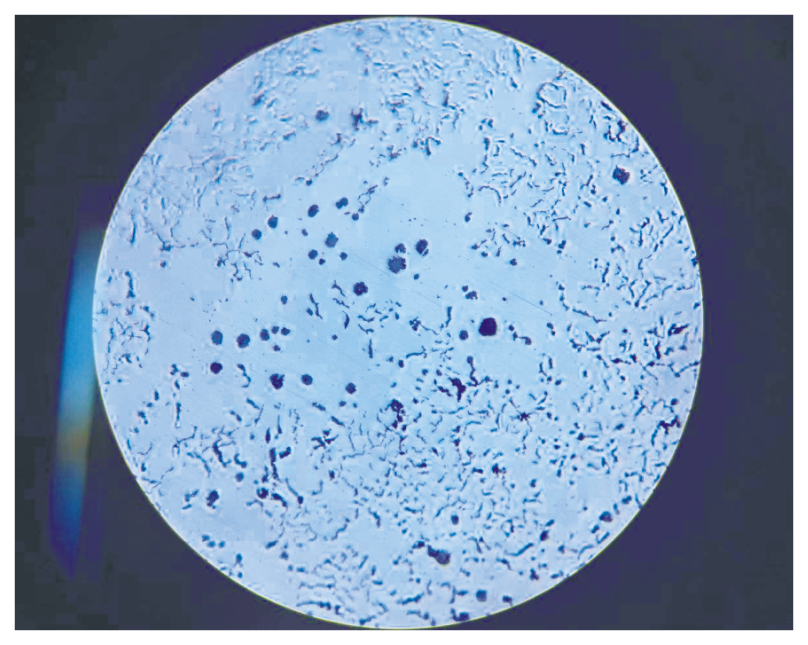

⑨ 球化率测试 Rate of spheroidization 每批次铸件球化率测试,不低于四级。 Test the rate of spheroidization every batch, less than level four. |

|

|

|

|

|

|

|

|

|

|

密封件硬度测试,确保零泄漏。 Hardness test for sealing part to zero leakage. |

|

|